“We use TM 190 mixer for our foundry operations. The mixer is equipped with fluid coupling drive. We had a history of frequent breakdown of mixer causing productivity loss.

DISA Aftermarket team came with a proposal to replace Fluid Coupling repair kit with Soft Starter kit.

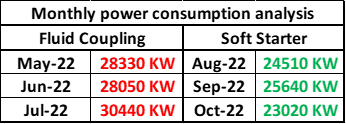

We are happy to see the overall improvement in the mixer and since installation, there is no breakdown reported and we happy to say, we are now saving approx.. Rs. 30,000/- per month with improved mixer performance.”

– Mr. D.M.Kumbhar, Manager Maintenance, Yash Metallics