Troubleshooting the foundry process

Despite having all the right ingredients for efficient production, issues were still creeping in. “We knew our DISA moulding machine was in perfect condition and we were happy with our control of the process,” explains the Quality Manager. “But despite this, we were having a lot of trouble with our casting quality. We had made some changes to our patterns but the scrap rate was still far too high.” This ongoing lower yield was losing the foundry money and causing downtime. It was time to call in expert help.

“We have a close relationship with our regional DISA base and turned to them for assistance,” continues the Quality Manager. “They suggested we talk to DISA Application about our problems.”

Wisdom on demand

DISA Application is a global consultancy service for owners of DISA and other brands of moulding equipment. Made up of the world’s best foundry troubleshooters, the Application team’s deep and broad knowledge of the entire casting process helps foundry owners improve all aspects of their foundry processes and performance.

Within days of the request, the Application team visited the foundry, analysed the process in detail and met with management. Though DISA were confident that they could help, the client was concerned that they might pay for consultancy but still not receive a solution to their problem. DISA offered a new alternative – a Win-Win contract.

Choosing a Win-Win solution

“With a Win-Win contract, instead of paying a consultancy day rate, the client pays by results,” explains Bo Haugbølle, Vice President of OEM Sales Support at DISA. “No win, no fee.

This arrangement means DISA Application is only paid when it improves the process, so we take the risk – not the client.” During the initial site visit, DISA’s consultant engineer agreed the project goals and how progress would be judged. Under the contract, the more DISA reduced defects and increased the yield, the more reward they would receive. The eventual target was an overall yield improvement of more than 5%. The only requirement was that the client follow DISA’s advice closely and work with the Application engineers to make the suggested improvements to their process.

Payment by results

“We saw immediately that there was no risk for us. It was simply a case of making sure we took the time to trial the improvements,” says the Maintenance Manager. “If the project worked, we would save a substantial amount of a money and DISA would be rewarded appropriately for their success. It was a very attractive solution for us.”

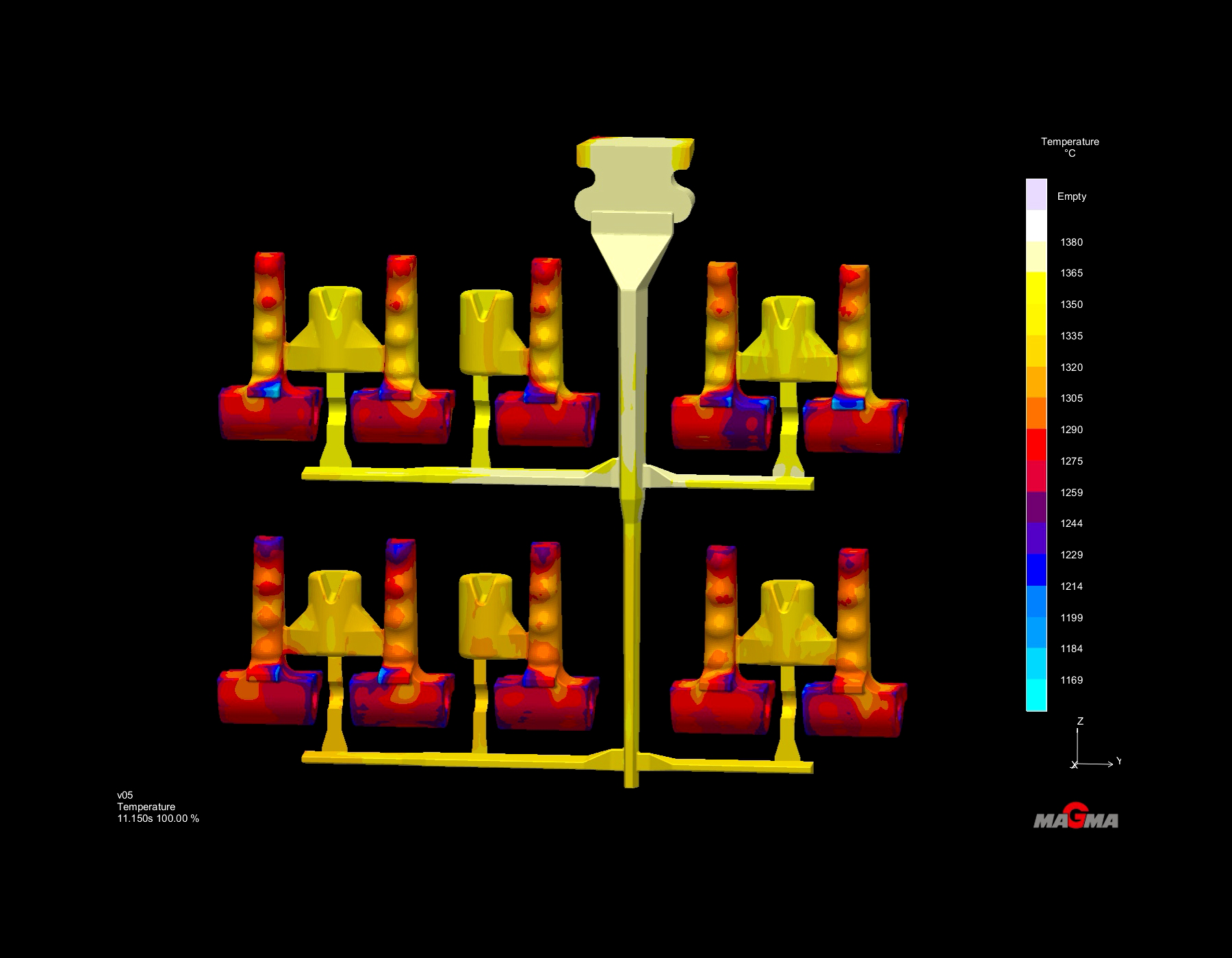

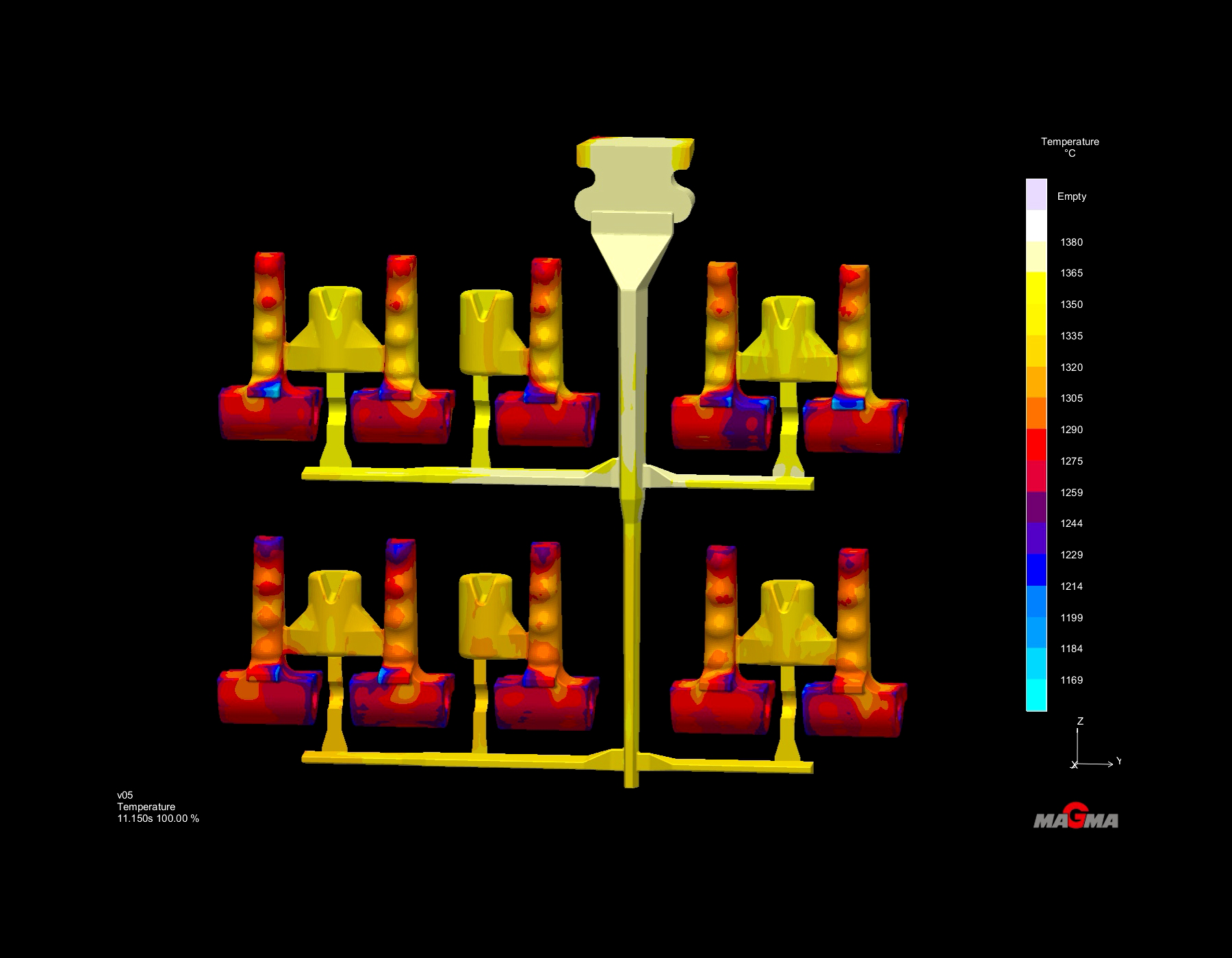

Over the following year, the Application consultants made four one-week site visits as well as conducting other remote conferences and face-to-face meetings with the client. They employed mass spectrometry analysis to reveal each casting’s chemical make-up while Magmasoft simulation software supported comprehensive 3D analysis of pattern and gating designs.

Adjustments were made in numerous areas, from mould thickness and hardness to inoculant sizing and pouring times. Pattern cleanliness, pouring times and cup design, cooling drum damage repair, core surface finish – the Application team evaluated and improved these along with many other process elements and parameters. However, it rapidly became clear that the current pattern designs, feeder necks and gating layouts were at the heart of the problem.

Optimising pattern design

In a process of incremental improvement, the DISA team generated new pattern designs, reviewed test results and re-ran sophisticated simulations in Magmasoft. Those results then informed the next set of designs along with suggestions for other process improvements. On site visits, Application engineers helped implement the changes and oversaw the next stage of testing.

“Their input gave us immediate improvements,” says the Quality Manager. “There were a few hiccups along the way but quality was obviously rising. In many cases, we needed new, completely redesigned patterns, along with a large number of other modifications, both small and large. As the engagement continued, the casting quality became better and better.”

Transforming casting quality

The engagement was extended for two months at the client’s request so the Application team could help with pattern and gating design for an important new component contract. The Application team logged their progress over the year, with the final results summarised in a Foundry Optimisation Report. This contained a logical, step-by-step analysis of each process and its parameters, clear explanation of the theories, observations, adjustments and tests applied, and a roadmap for future improvements.

DISA Application definitely delivered a win for the client. Yield improved by at least 8% and, in the case of one product, by 14%. Scrap also improved significantly, by over 20% for one product.

“The Win-Win contract really worked for us because it guaranteed we would only pay for the right results.” says the Maintenance Manager. “That’s exactly what we got. We’ve been able to see how effective the team are at solving foundry problems and are very happy with these excellent yield improvements. We are now moving to a standard day rate Application contract and will be working with DISA to optimise other foundry processes in the near future.”

Learning from the experts

“Our own engineers have learned a huge amount about the vertical process from DISA and we now completely trust the Application team to deliver results,” continues the Maintenance Manager. “I am very happy to recommend them to any foundry that wants to get the very best quality and productivity results.”